It’s been a wild summer and we’ve been trying to keep up with all that is going on around us, while still hoping to provide some great recipes and ideas you’ll enjoy! This week we wanted to do a Summer Round-up of yours—and our—favorites from the last several months.

This recipe, our Radler brined rack of ribs, was a huge hit! I hope some of you tried it or will try it soon!

Who doesn’t enjoy a homemade popsicle during the hot summer months? We were particularly proud of these beautiful and tasty pops made with Underwood Rosé and fresh berries—our Pink & Polka Dot Ice Pops.

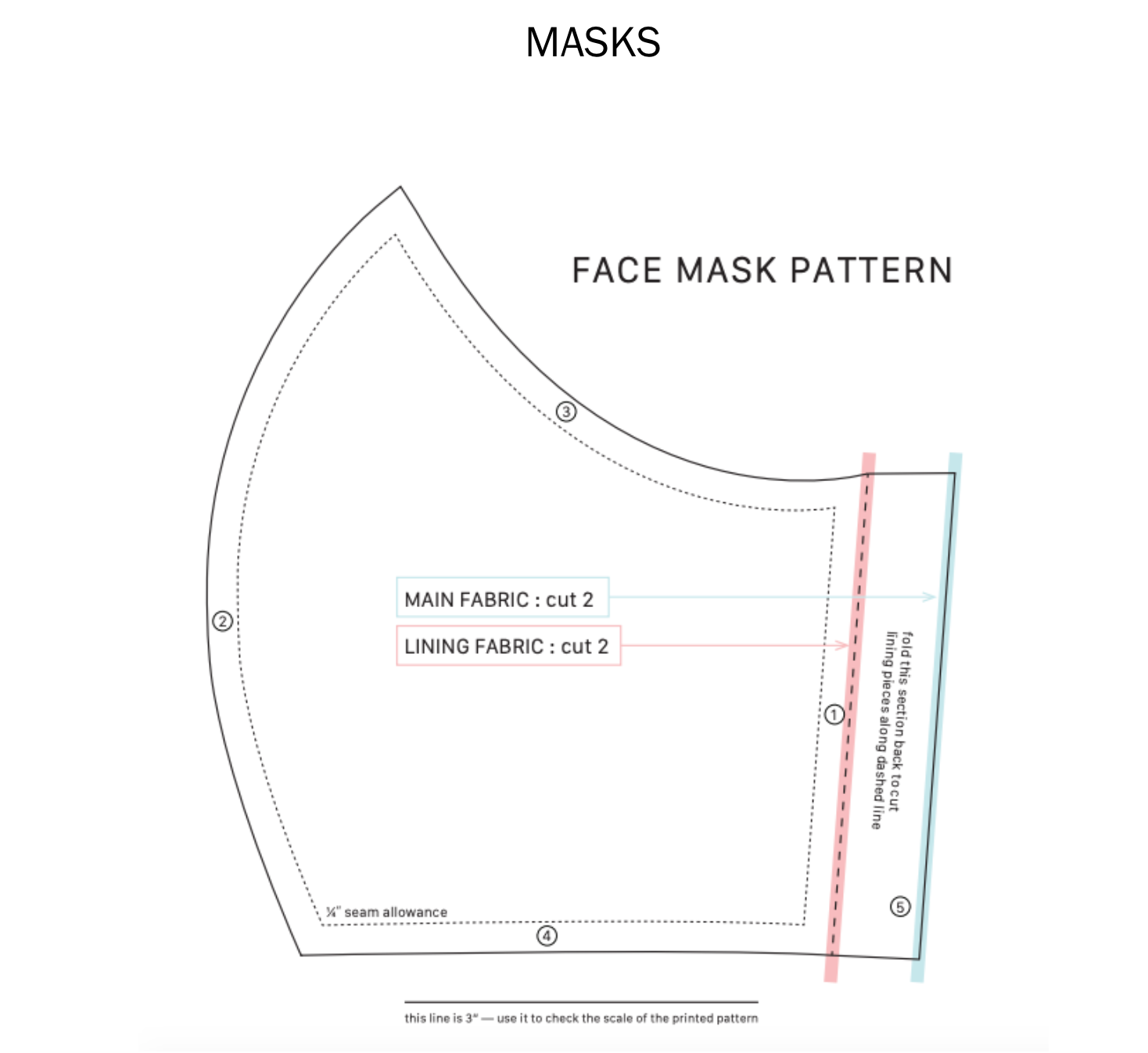

The times have certainly changed of late and we want to protect as many people as possible, starting with our employees. This post on how to get creative and make your own mask was educational and inspirational. Joanna is a pro at making fun and stylish masks and we were so happy she shared her sewing secrets with us.

And finally, who doesn’t love to follow along on other people’s adventures when they are as amazing as a day in the life of Cheney?! Cheney is a winemaker at Union and an active guy —it can be hard to keep up with him when he’s having fun. This post helps us enjoy the ride without going to too much trouble!

Those are our favorites. We hope you enjoy them as much as we did.

Take good care out there! Be careful and keep safe.

#pinkiesdown